Aqueous Ozone Applications

★★★★★

5.0 Rating

★★★★★

5.0 Rating

Contact Us

We’re here to help you create a cleaner, healthier environment—starting today.

Years Experience

Clean Smarter with Liquid Ozone

Aqueous Ozone Applications

Ongoing Support & Hygiene Consulting

A Safer Way to Disinfect Daily

Proven in Classrooms, Clinics, and Kitchens in Wisconsin

SAO Power

Stabilized Aqueous Ozone (SAO) technology provides up to 24 hours of active sanitization for everyday use.

Safe for All Surfaces

Approved for food contact surfaces and safe around children and pets, with no rinsing required.

Eco-Friendly & Cost-Effective

Saves on supply costs and waste, helping facilities reduce chemical storage and disposal needs.

Our Commercial Solutions

Tailored. Measurable. Chemical-Free.

Explore our specialized services designed for businesses, facilities, and critical industries. Each solution is built for performance, safety, and long-term results.

Custom Consulting & Installations

UV-C Air & Surface Disinfection

Aqueous Ozone Applications

Gaseous Ozone Fumigation

Our ozone gas treatments saturate the airspace and reach deep into HVAC ducts, equipment, and porous surfaces—destroying mold, bacteria, and viruses at the molecular level. Ideal for deep resets in food plants, labs, animal care, or buildings with persistent odor or contamination issues.

Proven Results from Real-World Application

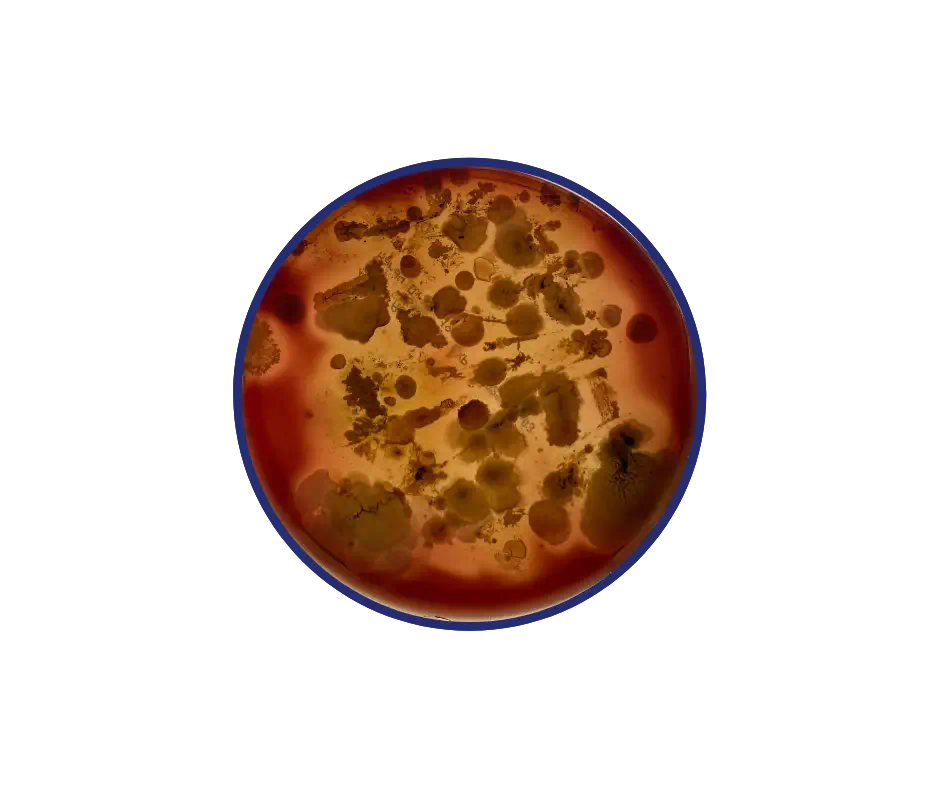

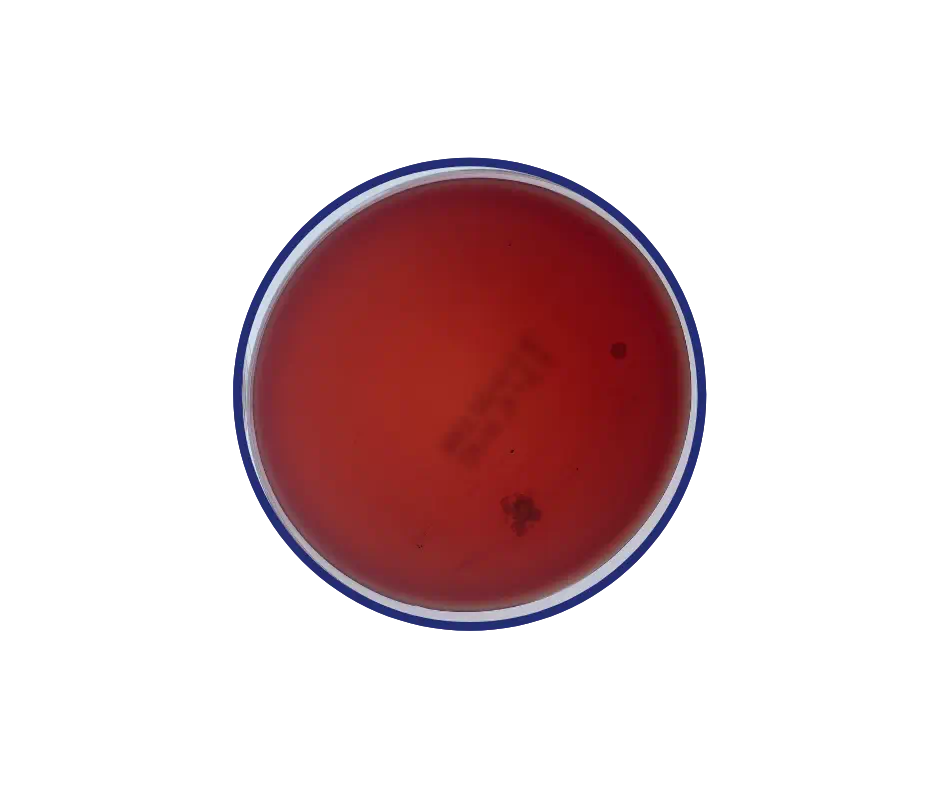

Daycare Study: A New Standard in Childcare Disinfection

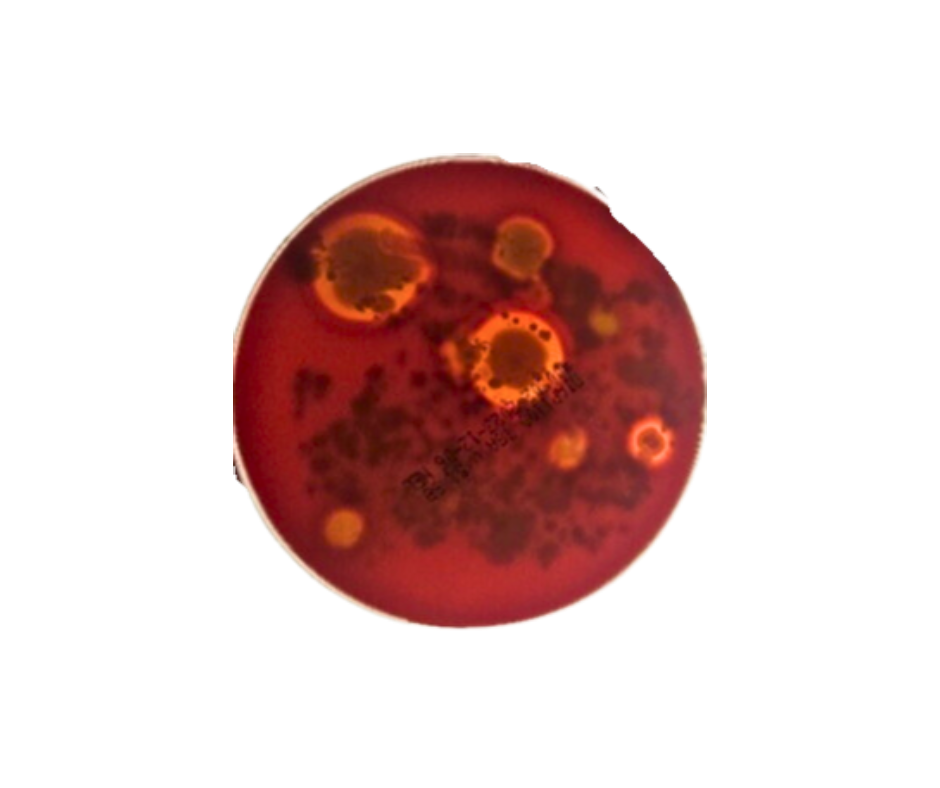

See the Science at Work

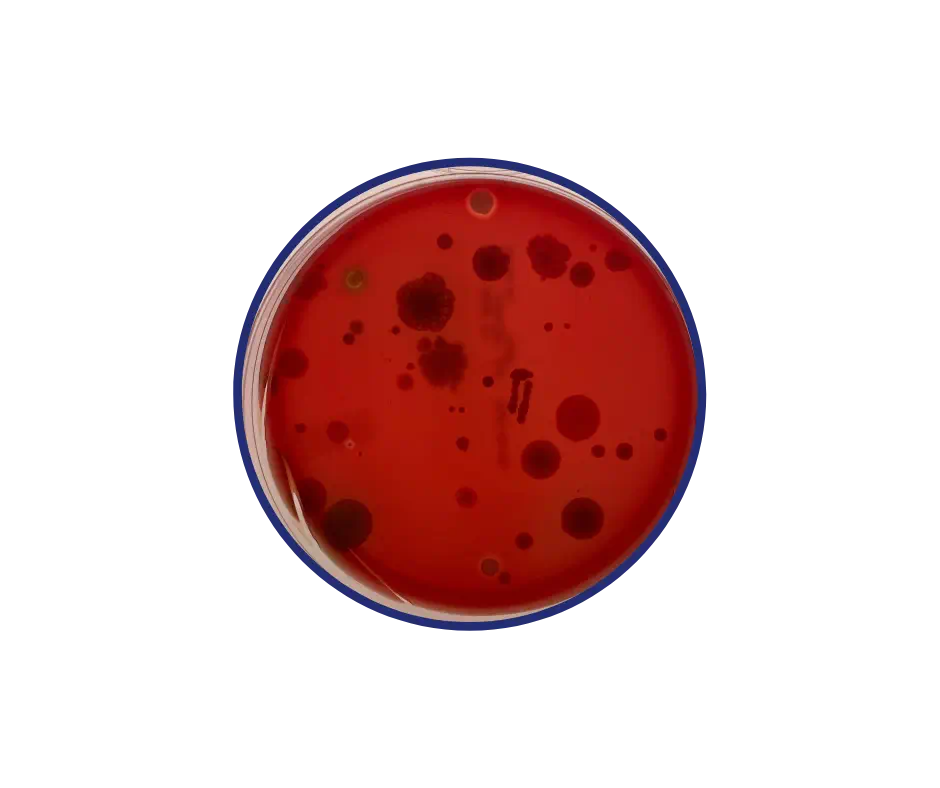

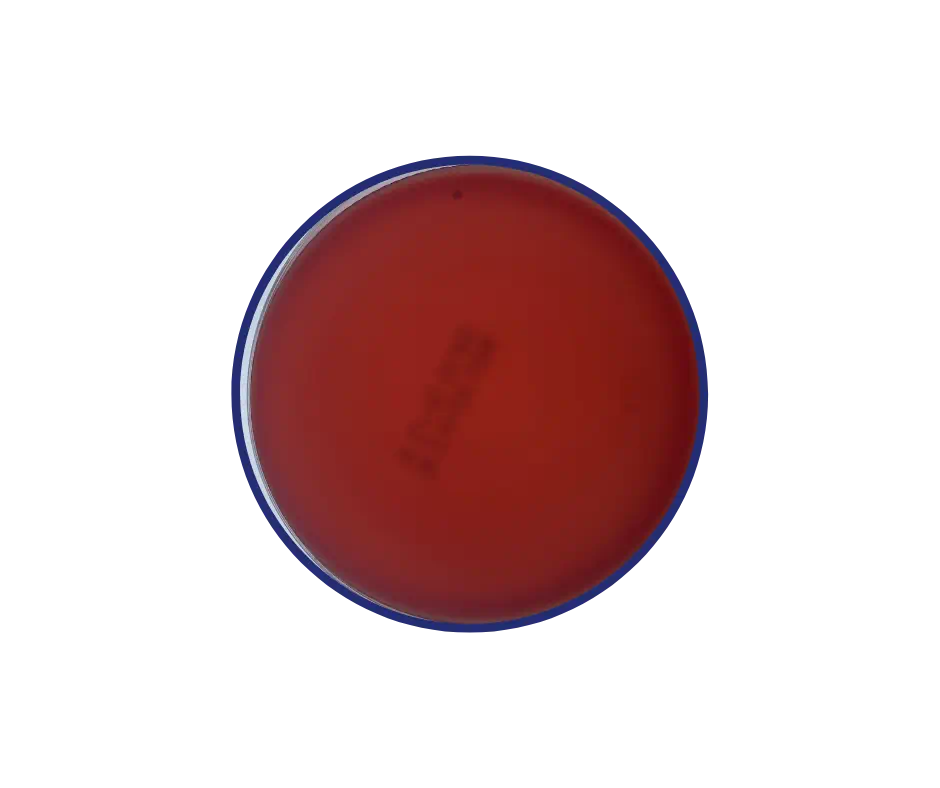

Before & After: Surface Test Plate Results