Gaseous Ozone Treatments in Wisconsin & Beyond

★★★★★

5.0 Rating

★★★★★

5.0 Rating

Contact Us

We’re here to help you create a cleaner, healthier environment—starting today.

Years Experience

Go Beyond the Surface

Industry Applications for Gaseous Ozone Fumigation

Ongoing Support & Hygiene Consulting

Deep Disinfection Where It Matters Most

Trusted by Facilities That Can't Afford Risk

Complete Penetration

Reaches areas that manual or spray disinfection cannot, including behind walls, inside vents, and within porous surfaces.

Residue-Free Disinfection

Neutralizes contaminants without harsh chemicals or post-treatment cleanup, just air and time.

Ideal for Reset or Recovery

Used for deep resets, emergency remediation, or scheduled decontamination in critical environments.

Our Commercial Solutions

Tailored. Measurable. Chemical-Free.

Explore our specialized services designed for businesses, facilities, and critical industries. Each solution is built for performance, safety, and long-term results.

Custom Consulting & Installations

UV-C Air & Surface Disinfection

Aqueous Ozone Applications

Gaseous Ozone Fumigation

Our ozone gas treatments saturate the airspace and reach deep into HVAC ducts, equipment, and porous surfaces—destroying mold, bacteria, and viruses at the molecular level. Ideal for deep resets in food plants, labs, animal care, or buildings with persistent odor or contamination issues.

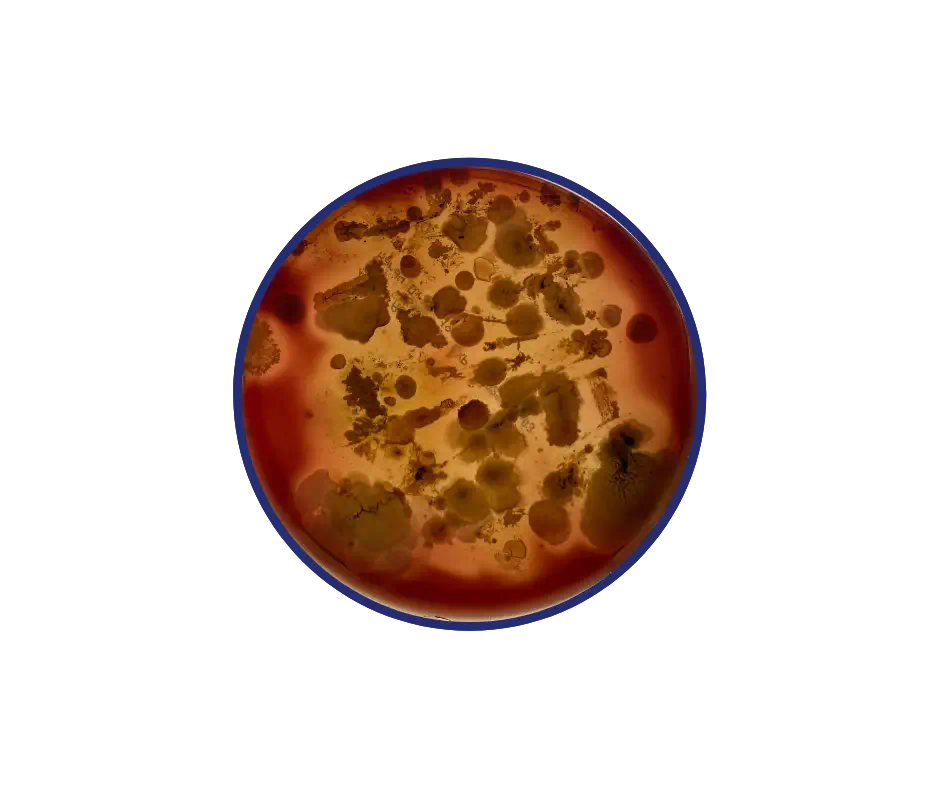

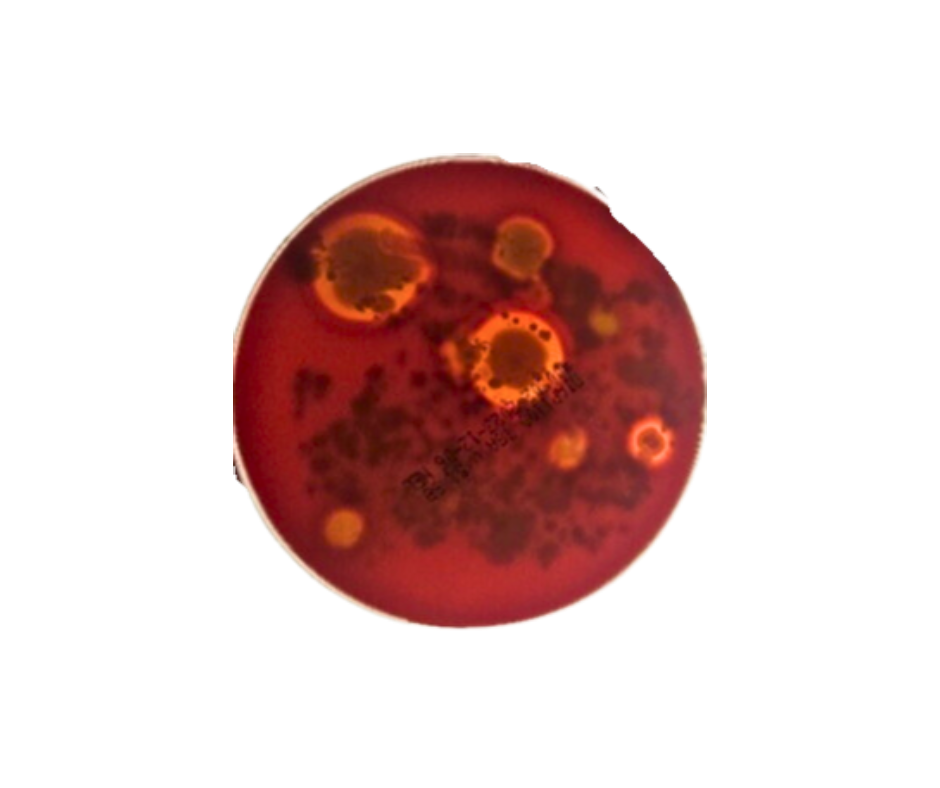

Proven Results from Real-World Application

Daycare Study: A New Standard in Childcare Disinfection

See the Science at Work

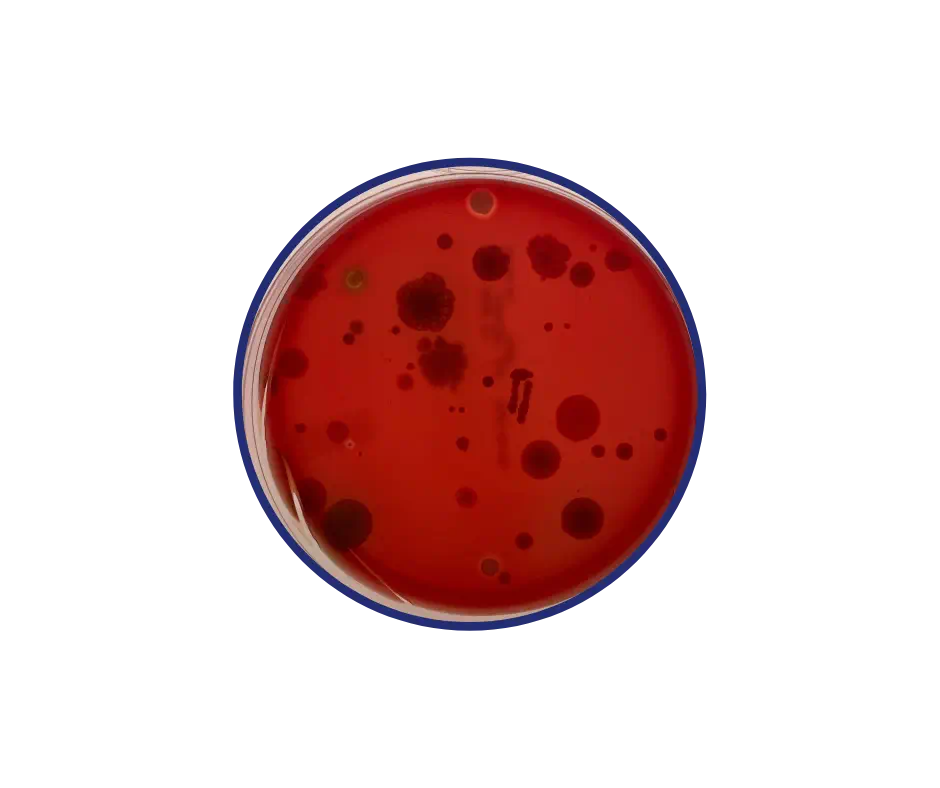

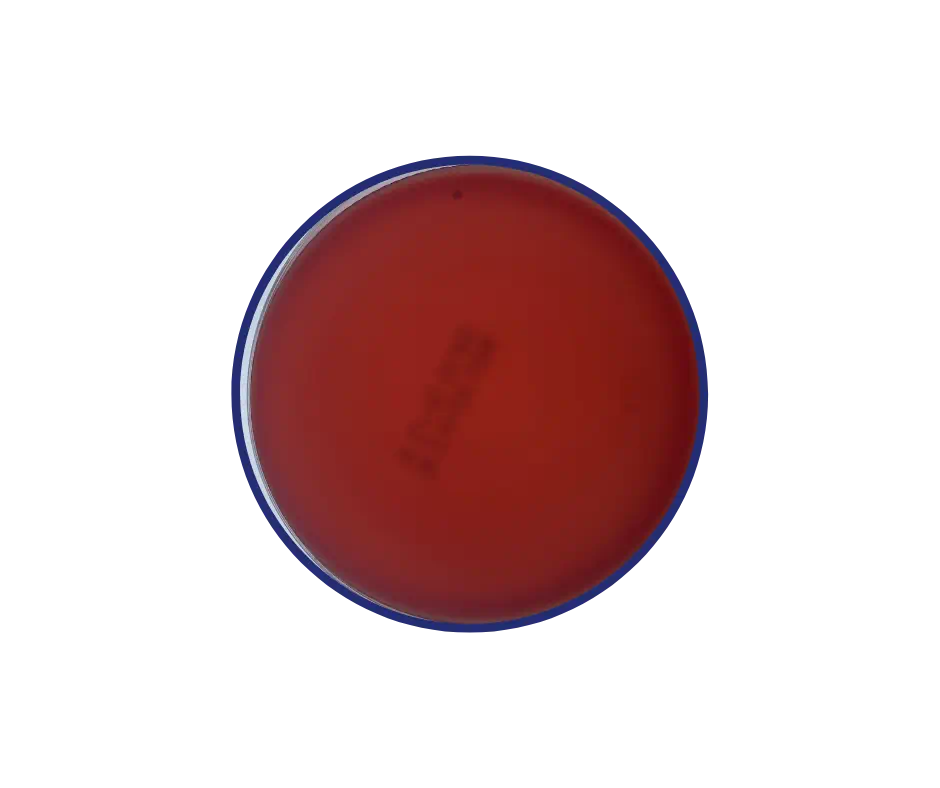

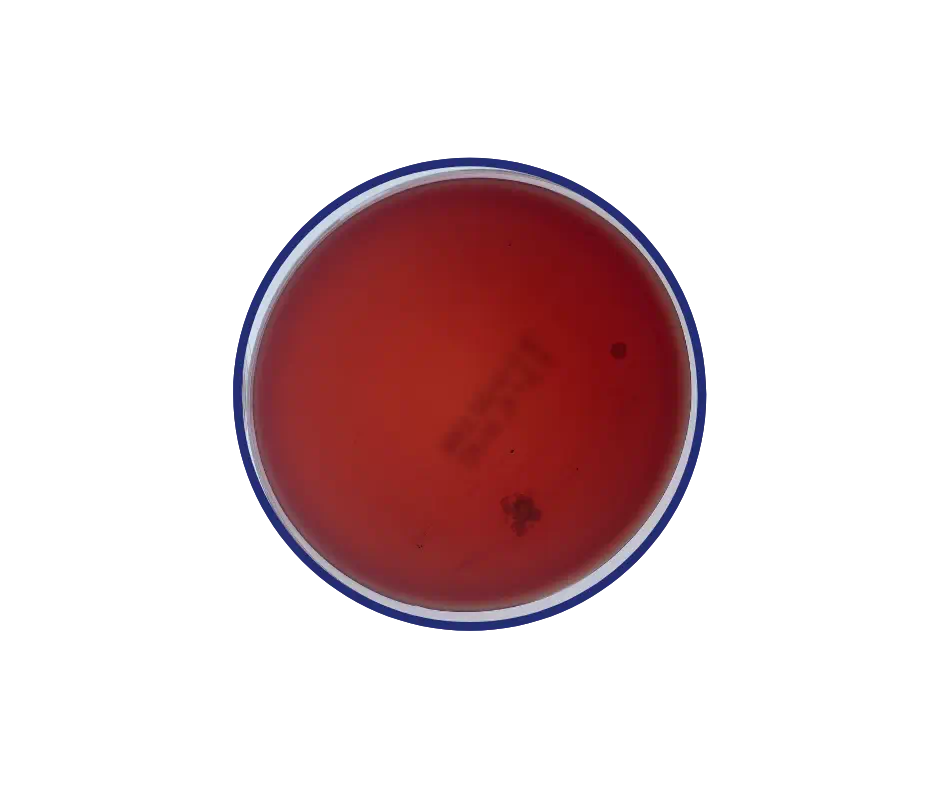

Before & After: Surface Test Plate Results