Commercial Disinfection Services in Wisconsin With UV-C & Ozone

At HS Ultra, we provide comprehensive commercial disinfection and sanitation services across Wisconsin, serving facilities in Milwaukee, Madison, Green Bay, Kenosha, Racine, and Appleton. Our team specializes in industrial and commercial cleaning solutions for a variety of sectors, including manufacturing, food production, healthcare, educational facilities, hospitality, and office environments. Using chemical-free methods like ozone cleaning, aqueous ozone disinfection, and UV-C sterilization, we eliminate harmful pathogens, bacteria, mold, and odors to protect employees, customers, and the environment. Whether you operate a large-scale industrial facility, a commercial office, or a public-facing space, HS Ultra delivers safe, sustainable, and effective commercial disinfection services that meet regulatory standards while ensuring measurable results and long-lasting protection.

Protect Your Facility Now

Protecting employees, customers, and operations across Wisconsin’s diverse commercial sectors

Tailored Commercial Disinfection Solutions for Every Industry

HS Ultra provides customized commercial disinfection and sanitation services designed to meet the unique needs of each industry we serve. From food processing plants and poultry facilities to biotech labs, medical equipment processing centers, and pharmaceutical packaging facilities, we implement advanced ozone cleaning, aqueous ozone sanitation, and UV-C disinfection to eliminate harmful pathogens and maintain regulatory compliance. We also support hospitals, elder care facilities, private schools, offices, wellness centers, gyms, and hospitality venues across Milwaukee, Madison, Green Bay, Kenosha, and Racine, ensuring safe, clean environments for employees, residents, students, and customers. By providing industrial and commercial disinfection services that are chemical-free, eco-friendly, and highly effective, HS Ultra helps businesses protect their operations, maintain trust, and minimize downtime while delivering measurable results.

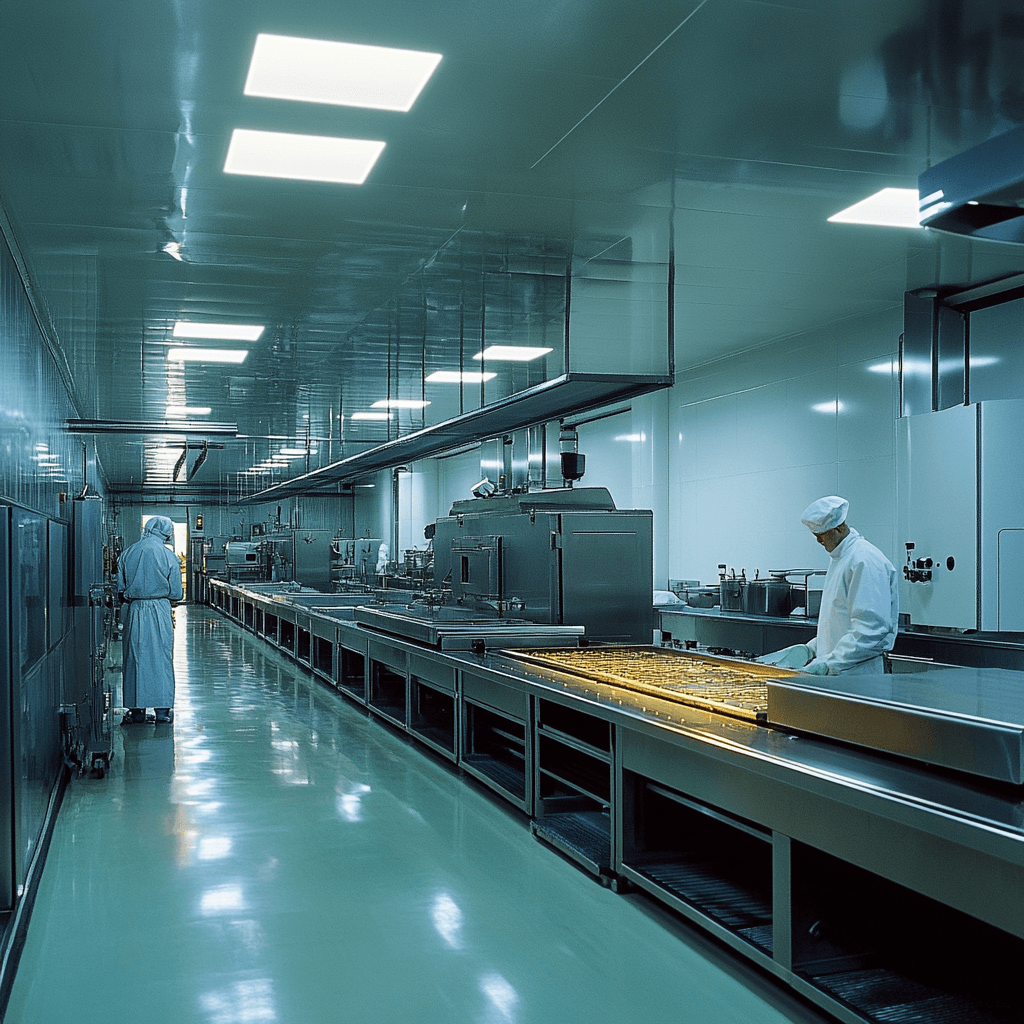

Industrial & Food Processing Facilities

Our industrial and food processing disinfection services are specifically designed to protect high-risk environments like poultry and livestock facilities, food processing plants, and pharmaceutical packaging centers. HS Ultra’s advanced sanitation methods eliminate Salmonella, Listeria, and other harmful pathogens, ensuring compliance with FDA, USDA, and HACCP standards while reducing contamination risk and production downtime.

Commercial & Public Spaces

HS Ultra also serves schools, offices, wellness centers, gyms, hospitals, elder care facilities, and hospitality venues, providing commercial disinfection services that protect employees, clients, and visitors. Our chemical-free, eco-friendly approach ensures safe spaces for public interaction while maintaining strict hygiene standards, helping businesses uphold trust and safety in every environment.

Comprehensive Disinfection for Safe, Healthy Workspaces

HS Ultra provides full-scale commercial disinfection services that go beyond standard cleaning to ensure your facility is safe, compliant, and ready for daily operations. Our chemical-free methods, including ozone cleaning, aqueous ozone sanitation, and UV-C disinfection, target pathogens, bacteria, mold, and odors at the source. Serving Milwaukee, Madison, Green Bay, Kenosha, Racine, and Appleton, we help businesses across Wisconsin maintain healthy environments for employees, customers, and residents alike.

Understanding Ozone and UV-C Disinfection

At HS Ultra, we leverage the power of ozone and UV-C disinfection to provide chemical-free, highly effective sanitation solutions for Wisconsin commercial and industrial facilities. Ozone cleaning works by generating O₃ molecules that penetrate surfaces, equipment, and hard-to-reach areas to neutralize bacteria, viruses, mold, and other harmful pathogens. This method is ideal for food processing plants, poultry and livestock facilities, pharmaceutical and biotech environments, and other industrial operations where contamination control is critical. UV-C disinfection, on the other hand, uses ultraviolet light at a specific wavelength to destroy the DNA and RNA of microorganisms, preventing them from reproducing and spreading. This technology is perfect for schools, offices, gyms, wellness centers, hospitals, and elder care facilities, ensuring rapid, safe, and effective sanitation of high-touch surfaces and air spaces. By combining ozone and UV-C disinfection, HS Ultra delivers a comprehensive approach that eliminates pathogens without leaving chemical residues, reduces downtime, and maintains compliance with regulatory standards. Serving Milwaukee, Madison, Green Bay, Kenosha, Racine, and Appleton, our team provides tailored solutions that protect employees, customers, and the environment, giving businesses the confidence to operate safely and efficiently.

Step-by-step chemical-free sanitation tailored to Wisconsin commercial and industrial facilities

Our Comprehensive Disinfection Process

At HS Ultra, our disinfection process is designed to deliver maximum protection and measurable results for every commercial and industrial facility we serve across Wisconsin, including Milwaukee, Madison, Green Bay, Kenosha, Racine, and Appleton. We begin with a thorough assessment of your space, identifying high-risk areas, equipment, and surfaces that require targeted sanitation. Next, our team applies advanced ozone cleaning, aqueous ozone applications, and UV-C disinfection methods, eliminating bacteria, viruses, mold, and odors without harmful chemicals. Each step is tailored to the unique needs of your facility, whether it’s a food processing plant, biotech lab, school, office, or wellness center, ensuring compliance with regulatory standards and industry best practices. From preparation and application to verification and reporting, our hands-free, science-backed approach guarantees that your facility remains safe, hygienic, and operationally efficient, providing peace of mind for employees, customers, and clients alike.

Benefits of Chemical-Free Disinfection

HS Ultra’s chemical-free disinfection solutions offer unparalleled safety, efficiency, and sustainability for Wisconsin commercial and industrial facilities, including Milwaukee, Madison, Green Bay, Kenosha, Racine, and Appleton. By using ozone cleaning, aqueous ozone applications, and UV-C sterilization, we eliminate harmful pathogens, bacteria, and mold without introducing harsh chemicals that can damage surfaces, equipment, or indoor air quality. This approach is ideal for high-risk environments such as food processing plants, poultry facilities, biotech labs, medical offices, schools, gyms, and hospitality venues, where employee and customer safety is paramount. Chemical-free disinfection reduces exposure to toxic residues, supports environmentally responsible practices, and allows facilities to remain operational with minimal downtime. Beyond safety and sustainability, our solutions provide consistent, measurable pathogen control, ensuring that your facility remains compliant with regulatory standards while protecting the health of employees, clients, and visitors.

Seasonal and High-Risk Area Disinfection

HS Ultra provides specialized disinfection services for seasonal and high-risk areas where pathogens are more likely to spread. During flu season, periods of heightened illness, or following biohazard events, our team implements targeted sanitation protocols to reduce the risk of contamination in facilities. Using ozone cleaning, aqueous ozone applications, and UV-C disinfection, we sanitize high-touch surfaces, shared equipment, and communal spaces to ensure safe environments for employees, clients, and visitors. Whether it’s classrooms, fitness centers, office spaces, or healthcare settings, our proactive approach helps minimize downtime, prevent outbreaks, and maintain operational continuity. By addressing high-risk areas promptly and thoroughly, HS Ultra delivers peace of mind and measurable protection for your business or organization.

Poultry and Food Processing Facility Disinfection

HS Ultra provides comprehensive disinfection and sanitation services specifically designed for poultry farms and food processing facilities, where maintaining pathogen-free environments is critical to product safety, employee health, and regulatory compliance. Facilities in these industries face unique challenges, including high-density animal housing, complex processing equipment, and constant human interaction, all of which can facilitate the rapid spread of harmful bacteria such as Salmonella, Listeria, and E. coli. Our chemical-free approach utilizes ozone cleaning, aqueous ozone applications, and UV-C disinfection to reach every surface, crevice, and high-touch area, eliminating pathogens without leaving harmful residues.

In addition to pathogen control, HS Ultra’s solutions help prevent cross-contamination between production lines, storage areas, and shipping zones, which is essential for avoiding product recalls and protecting brand reputation. By implementing regular sanitation schedules and targeted deep-cleaning treatments, we support facilities in meeting FDA, USDA, and HACCP standards, as well as other industry-specific compliance requirements. Our services also reduce downtime by using fast-acting, hands-free technologies that allow operations to resume safely and efficiently.

Beyond immediate sanitation, HS Ultra helps poultry and food processing facilities maintain long-term hygiene and operational efficiency. From pre-production preparation to post-production cleanup, our team develops customized protocols that address each facility’s unique layout, equipment, and risk factors. Whether it’s cleaning processing lines, storage bins, transport vehicles, or employee common areas, our combination of UV-C sterilization, ozone, and aqueous ozone cleaning ensures that both the environment and personnel are protected. With HS Ultra, facilities gain peace of mind knowing that they are minimizing contamination risks, safeguarding product integrity, and promoting a healthy workplace for employees, all while using eco-friendly, chemical-free solutions.

Medical, Laboratory, and Cleanroom Disinfection

HS Ultra delivers specialized disinfection and sanitation services for medical offices, dental and chiropractic clinics, hospitals, biotech laboratories, pharmaceutical and nutraceutical packaging facilities, and cleanrooms, where maintaining absolute sterility is critical. These environments face unique challenges, including high-touch medical equipment, sensitive instrumentation, and strict regulatory standards, all of which require precise and thorough sanitation. Using chemical-free solutions such as ozone cleaning, aqueous ozone applications, and UV-C disinfection, our team targets bacteria, viruses, mold, and other pathogens on surfaces, in the air, and throughout hard-to-reach areas, reducing contamination risks without introducing harsh chemicals that could damage equipment or compromise sterility.

Medical and laboratory facilities must comply with stringent regulations such as FDA, ISO, and cGMP standards, and even minor lapses in sanitation can result in costly setbacks, product recalls, or compromised patient safety. HS Ultra’s methods ensure that every surface, room, and piece of equipment is cleaned and sterilized to the highest standards, supporting regulatory compliance while maintaining operational efficiency. Our hands-free, science-backed approach allows facilities to continue operating with minimal disruption, protecting staff, patients, researchers, and sensitive products alike.

Cleanrooms and controlled laboratory environments particularly benefit from HS Ultra’s advanced technologies. UV-C light sterilization destroys microorganisms at the DNA and RNA level, preventing reproduction and spread, while ozone and aqueous ozone treatments provide deep penetration into equipment, ventilation systems, and storage areas that traditional cleaning often misses. By combining these methods, HS Ultra delivers a comprehensive, chemical-free sanitation program that minimizes

Cost-Effective Sanitation Solutions

At HS Ultra, we understand that sanitation isn’t just about safety — it’s also about protecting your bottom line. Traditional cleaning methods can be time-consuming, labor-intensive, and reliant on costly chemical products that require constant reordering. Even worse, they often fail to fully eliminate pathogens, creating hidden risks that can lead to downtime, product loss, or compliance issues. Our advanced sanitation technologies — including ozone cleaning, aqueous ozone applications, and UV-C disinfection — are designed to provide a smarter, more cost-effective solution that not only achieves a higher level of cleanliness but also reduces ongoing operational expenses. By eliminating the need for harsh, single-use chemicals, HS Ultra helps businesses lower supply costs, reduce waste, and create a more sustainable sanitation program.

In industries where productivity is tied directly to facility uptime — such as healthcare, manufacturing, laboratories, and food production — downtime caused by outbreaks, contamination, or regulatory failures can be extremely costly. HS Ultra’s rapid, chemical-free cleaning solutions are designed to minimize disruption by sterilizing spaces quickly and efficiently, allowing your operations to resume faster and with greater confidence. Our methods target both surfaces and airborne pathogens, reducing the likelihood of recurring contamination that could slow production, endanger staff, or require repeat cleanings. By keeping facilities safer and more compliant, businesses can avoid costly shutdowns, product recalls, or reputational damage, all while improving day-to-day efficiency.

The return on investment is clear: fewer chemicals purchased, less labor required for repetitive cleaning tasks, reduced environmental impact, and a significantly lower risk of downtime or compliance penalties. Many facilities also benefit from improved employee wellness and reduced absenteeism, as safer, cleaner spaces lower exposure to harmful pathogens and allergens. Over time, these benefits add up to substantial cost savings and operational resilience. At HS Ultra, we don’t just provide cleaning — we provide a strategic sanitation program that enhances performance, protects your people, safeguards your reputation, and maximizes every dollar spent.

Employee Safety and Wellness Benefits

At HS Ultra, we understand that protecting the health and well-being of your workforce is just as important as keeping your facility sanitized. Traditional chemical-heavy cleaning methods often expose employees to harsh substances that can cause skin irritation, respiratory issues, or long-term health concerns. Our advanced, eco-friendly sanitation systems eliminate those risks by replacing harmful chemicals with safer alternatives such as aqueous ozone and UV-C light. This creates a healthier indoor environment with cleaner air quality and reduced chemical residue on surfaces and equipment. Beyond the physical health advantages, safer sanitation methods also improve morale and productivity by showing employees that their employer prioritizes their safety and comfort. A workplace free from chemical odors, irritants, and unnecessary exposure means fewer sick days, lower turnover, and a more engaged, motivated staff. In industries like healthcare, laboratories, cleanrooms, and food production—where employees already face high demands—providing a safer, cleaner, and more supportive environment translates directly into better performance, reduced liability, and long-term operational success. By choosing HS Ultra, you’re not only protecting your facility from contamination—you’re protecting your people.

Turning Cleanliness Into Measurable Confidence

Data-Driven Sanitation: Monitoring and Validation

At HS Ultra, we believe that effective sanitation is more than a promise—it should be proven with measurable results. That’s why our solutions are designed with data-driven monitoring and validation at their core. Unlike traditional cleaning methods, which often rely on visual inspection alone, our systems incorporate advanced testing, tracking, and verification tools to ensure that every surface and environment meets the highest hygiene standards. Real-time monitoring provides accurate insights into microbial load, air and surface quality, and sanitation performance. Validation reports can be used to demonstrate compliance with regulatory standards, reassure customers and auditors, and guide continuous improvement. This level of transparency is especially valuable in industries like healthcare, cleanrooms, food production, and pharmaceuticals, where even the smallest lapse in sanitation can have serious consequences. By leveraging data, HS Ultra helps businesses not only meet but exceed compliance requirements, reduce liability, and maintain a competitive edge. With a fully validated process, cleanliness is no longer subjective—it’s proven, documented, and dependable.

Long-Term Value: Extending Equipment and Facility Life

One of the most overlooked benefits of advanced disinfection is its ability to protect the long-term integrity of equipment and facilities. At HS Ultra in Wisconsin, our chemical-free, non-corrosive sanitation methods are designed to safeguard sensitive machinery, structural materials, and production environments from the wear and tear caused by harsh cleaning agents or outdated processes. Traditional chemical sanitizers can erode surfaces, damage seals, and shorten the lifespan of costly equipment, leading to expensive repairs and replacements over time. By contrast, our gentle yet highly effective technologies minimize material degradation while maintaining the strictest hygiene standards. This approach not only extends the useful life of machinery and infrastructure but also helps businesses avoid costly downtime caused by breakdowns or maintenance issues. Over the years, these savings add up to a significant return on investment, making our process not just a health and safety solution but also a smart financial strategy. Whether for food processors, cleanrooms, or healthcare facilities across Wisconsin and beyond, HS Ultra provides sanitation solutions that protect your people, your products, and the long-term value of your assets.

Customizable Sanitation Programs

Every facility has unique sanitation challenges, and HS Ultra recognizes that a one-size-fits-all approach doesn’t deliver the best results. That’s why we design customizable sanitation programs tailored to the specific needs of your industry, facility layout, and risk profile. Whether you operate a poultry processing plant, a medical lab, or a cleanroom environment in Wisconsin, our team works with you to create a plan that ensures maximum protection, efficiency, and compliance with strict regulatory standards. By integrating flexible scheduling, targeted applications, and specialized equipment, we help you maintain a consistent, reliable sanitation routine that adapts to seasonal demands or evolving operational needs.

To make customization easier, our programs can include:

- Flexible Scheduling: Adjust frequency based on production cycles or seasonal risks.

- Industry-Specific Protocols: Aligning with USDA, FDA, or ISO requirements.

- Scalable Solutions: From small labs to large-scale food facilities, we adapt to your operation’s size and scope.

- Data & Reporting: Detailed sanitation logs and validation records to support compliance and audits.

- Employee Training Support: Ensuring your staff understands best practices for safety and efficiency.

By offering these adaptable solutions, HS Ultra ensures that businesses across Wisconsin and beyond not only meet today’s sanitation requirements but also stay prepared for tomorrow’s challenges.

Frequently Asked Questions

HS Ultra provides sanitation and blasting solutions across a wide range of industries, including food and poultry processing, medical labs, pharmaceutical cleanrooms, and industrial facilities. Because every sector has unique compliance and safety requirements, we tailor our processes to meet industry-specific standards such as USDA, FDA, and ISO guidelines, ensuring both effectiveness and regulatory compliance.

Our services are designed with efficiency in mind. By reducing contamination risks and minimizing downtime, HS Ultra helps facilities in Wisconsin and surrounding regions maintain smooth production schedules. Our precise sanitation methods not only extend the life of equipment but also prevent costly interruptions, giving clients a measurable return on investment through improved productivity and reduced maintenance needs.

Yes. HS Ultra prioritizes eco-conscious practices by using cleaning methods and products that are effective against pathogens while minimizing environmental impact. We carefully select processes that reduce water usage, limit harsh chemical dependency, and improve air quality within facilities. This approach supports both compliance with environmental regulations and a healthier workplace for employees.

Absolutely. HS Ultra specializes in customizable sanitation programs that adapt to your specific facility, whether it’s a poultry processing plant, medical lab, or cleanroom environment. We adjust service frequency, protocols, and reporting tools based on your risk profile, production cycle, and regulatory requirements. This ensures you receive a solution that’s both cost-effective and highly effective in maintaining long-term cleanliness and safety.

Regulatory Compliance Assurance

Navigating the complex landscape of sanitation regulations can be overwhelming for any business, especially in industries where strict health and safety standards are non-negotiable. At HS Ultra, we provide peace of mind by ensuring your facility meets or exceeds all applicable guidelines set forth by agencies such as the USDA, FDA, OSHA, and ISO. Our sanitation programs are carefully designed to align with these regulations, reducing the risk of violations, costly fines, or downtime caused by failed inspections. Beyond meeting basic requirements, we maintain detailed documentation and reporting for every service, giving you a transparent record that supports audits and demonstrates compliance at every stage. By staying up to date with evolving industry standards, HS Ultra helps companies across Wisconsin protect their operations, safeguard their employees and customers, and build a reputation for reliability and trustworthiness.

Local Expertise and Community Commitment

At HS Ultra, we take pride in being more than just a service provider—we’re a part of the Wisconsin community we serve. Our team understands the unique needs and challenges that local businesses face, from food processing plants in rural areas to high-traffic healthcare facilities in urban centers. This local expertise allows us to deliver sanitation solutions that are not only effective but also tailored to the specific environments in which our clients operate. Beyond our services, we are deeply committed to supporting the communities where we live and work, building lasting relationships based on trust, reliability, and accountability. By choosing HS Ultra, you’re not only partnering with a company that has the technical skill and industry knowledge to keep your facility safe—you’re also supporting a team that is dedicated to the well-being and growth of the Wisconsin communities we proudly call home.

Industry-Specific Sanitation Programs

At HS Ultra, we recognize that every industry faces unique sanitation challenges, which is why we develop customized programs tailored to your specific needs. From food processing plants and poultry facilities to medical labs, cleanrooms, and wellness centers, our solutions are designed to meet the strict hygiene standards required in each environment. We assess your facility, identify high-risk areas, and implement a combination of UV-C disinfection, ozone cleaning, and aqueous ozone applications to ensure comprehensive pathogen control.

Our industry-specific programs include:

Food & Poultry Processing: Targeting Salmonella, Listeria, and other contaminants to protect products and maintain regulatory compliance.

Medical & Pharmaceutical Facilities: Sterilizing labs, cleanrooms, and equipment to prevent cross-contamination and meet FDA/ISO standards.

Industrial & Manufacturing: Deep-cleaning high-touch surfaces, machinery, and common areas to reduce operational risk and downtime.

Wellness Centers & Fitness Studios: Ensuring safe, pathogen-free environments for staff and clients through hands-free chemical-free sanitation.

By tailoring our services to each industry, HS Ultra ensures maximum effectiveness, efficiency, and compliance, giving businesses across Wisconsin and surrounding areas the confidence that their facilities are not only clean but fully protected.

Protecting Your Facility, Products, and People

Minimizing Cross-Contamination Risks

At HS Ultra, we understand that cross-contamination can have serious consequences, especially in industries such as food processing, pharmaceuticals, biotech labs, and healthcare facilities. Even a small lapse in sanitation can spread harmful pathogens like Salmonella, Listeria, or viruses across surfaces, equipment, and production lines, putting products, employees, and customers at risk. Our advanced chemical-free disinfection methods, including ozone cleaning, aqueous ozone applications, and UV-C sterilization, are specifically designed to reach every corner of your facility, ensuring comprehensive pathogen control. By implementing targeted sanitation protocols, specialized equipment cleaning, and precise scheduling, we significantly reduce the risk of cross-contamination between zones, machinery, and personnel. For facilities across Wisconsin and nearby regions, this translates into safer operations, better regulatory compliance, and reduced likelihood of costly recalls, shutdowns, or health incidents. HS Ultra’s hands-free, data-driven approach not only eliminates pathogens but also creates long-lasting, reliable protection, helping businesses maintain the highest standards of cleanliness and operational integrity.